A Touchy Subject

Finally got a chance to link in the Or gate as the original schematics showed, and that seemed to help alleviate the problems I was seeing, but another problem showed itself. I’d seen something like this before, but tonight it was more apparent what the behavior is, if not the cause. It seems like there’s some strange issue with my breadboard, causing the behavior of the circuit to change depending on whether I am physically touching the top of the surface of the board or not. I tried grounding it, but that just made it stop working all together. So, touch the surface, and it works, stop touching, it stops working. Something’s definitely fishy, and I can’t really tell if I’ve wired something wrong or if I just need to replace the breadboard. Will probably try something else soon, even if it’s just soldering the works together.

Such Cutting Remarks

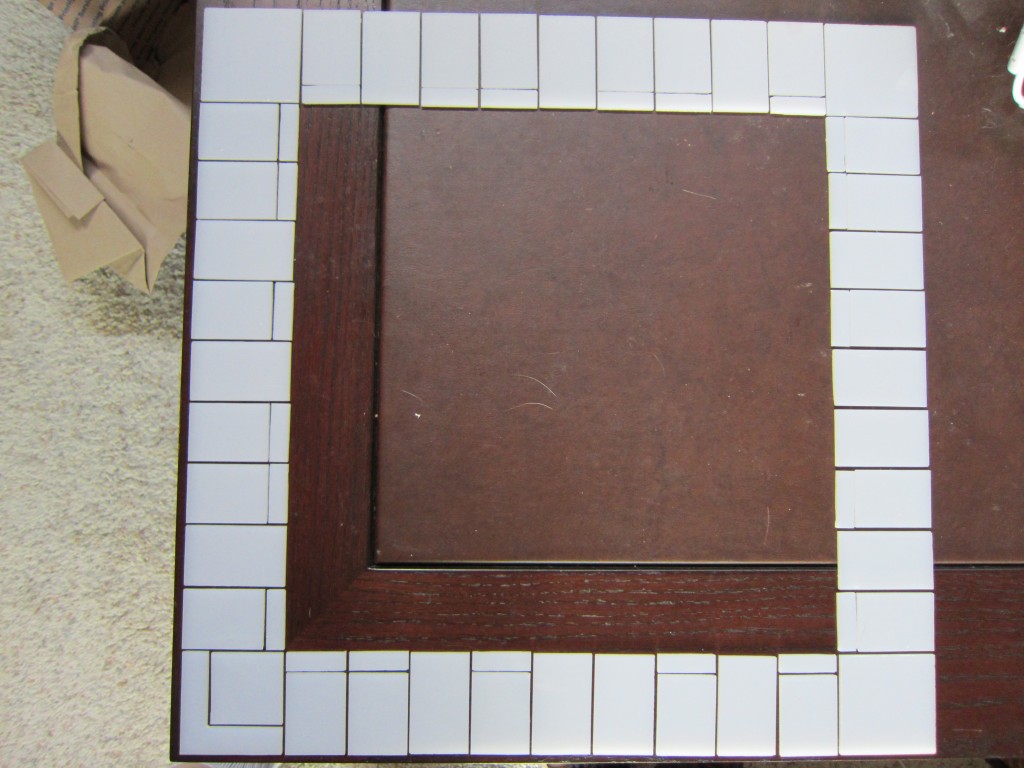

So, first round of acrylic cutting is pretty much done, although I may want to redo some of the pieces. I’m using a white acrylic that’s about 1/8 inch thick for the actual spaces, and tried to get these things cut to a pretty tight tolerance. Here’s how they look laid out without any actual support.

Not too bad, although I’m disappointed that it seems like my measurements for the property spaces didn’t quite line up with the measurements for the others. I may have to shave down the lower parts of them to make it all line up well. (I’d rather not make the color bars any smaller than they are; those tiny pieces are fiendish to work with.)

That being said, I may be recutting the color bars anyway, if I can find enough material. The ones that I cut this time didn’t come out quite as sharp as I’d hoped. I was doing an initial rip cut on the table saw, then doing the final cuts on a miter saw. Unfortunately, when the miter saw completes its cut, these pieces are so small they fly away, and this tended to involve the blade making contact along an edge and leaving a gouge, which doesn’t look very nice. I’ll probably hold off on doing any further cuts on this material until I have the actual base ready to go so I can make sure future pieces fit snugly.

If I do recut the color bars, I’ll probably end up redoing them more in line with how I cut the Jail/Just Visiting space. I went over a few possibilities, and ended up building a small jig to carry the piece through the table saw. I used a couple of pieces of scrap acrylic (clear) to sandwich the white piece between, set the fence and the blade to the exact width and height of the cut, and used the miter gauge to push it through upright. This gave me a cut at the right distance and the right depth to cleanly slice out the jail space and leave a pretty L-shaped Just Visiting space. This resulted in a much cleaner cut than the miter saw was making, and kept the remaining piece from flying across the garage.

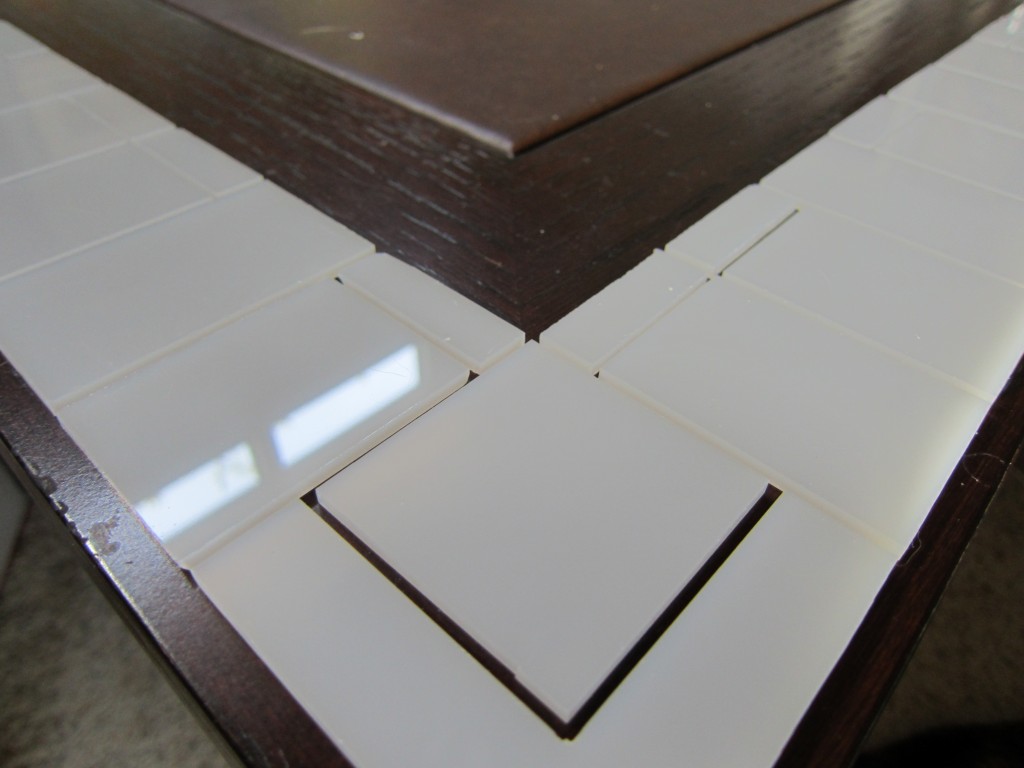

One more shot to wrap it up for today, showing some dynamic perspective!

Follows Directions

Got the new oscillators in the mail today, and swapped them into the circuit. Much more reliable behavior, but still wasn’t quite as I expected. So, I finally buckled down and went back to one of my original sources and made a stronger effort to faithfully replicate the circuit as presented. Well, nearly faithfully. I haven’t got the Not or Or gates in place, but seem to be doing okay enough for the moment. I also connected the line running Blank on the TLC5941 to also hit the Reset input on the 4060 so that I can immediately restart the cycle of 4096 rather than waiting for the counter to get back up to that point again. May not be completely necessary, but I wanted to maintain the full range of brightness possible. Regardless, some measure of success! Hooray!

Still a few glitches in the system. When I tried to only light a few LEDs, the others would periodically flash on briefly. I expect this may be due to my ignoring the warning to only send the XLAT command while Blank is active. To do that, I’ll need to put that Or gate in place. Should have a few laying around somewhere. Also, I should run some tests on just leaving the Blank set for longer; that could actually give me greater brightness control if, as I suspect is the case, the whole Persistence of Vision thing means that brightnesses between 50% and 100% are virtually indistinguishable. Should be some good testing, regardless. For tonight, though, the core lesson of “Get what you’ve read about working before tinkering with it” is once again learned.

(And promptly forgotten.)

Now That’s What I Call a Sticky Situation!

One of the concerns I’ve had with lighting the spaces is making sure that I don’t end up with dark lines around the edges that aren’t lit as well as the main body of the space. In the old board, there were plywood supports at the top and bottom which severely ate into the lighted area. For this project, I was planning to use transparent acrylic to provide the supports for the top of each space to allow light to shine through. (This is as opposed to simply gluing the top spaces in place, which I wanted to avoid just in case I needed to replace one at some point. Why would I need to? No idea. But why remove the possibility?)

Fortunately, a trip to a local hobby store gave me what seems to be an ideal solution to both that problem, and the problem I found of needing to have the interior of each space be white to provide light reflection. Back in the model train section, they have lots of raw materials used for building roads, bridges, buildings, hills, and all sorts of other things you’d see in a model train setup. One of their materials is a simple white styrene sheet. Which is just a tiny fraction of an inch thick. You can cut the stuff with scissors. Eureka! I use this to make the inside of the box white, and those tiny fractions of an inch can provide the support I need without overly impacting the light diffusion. Surely the thickness of the top plastic will make up for that tiny ledge, right?

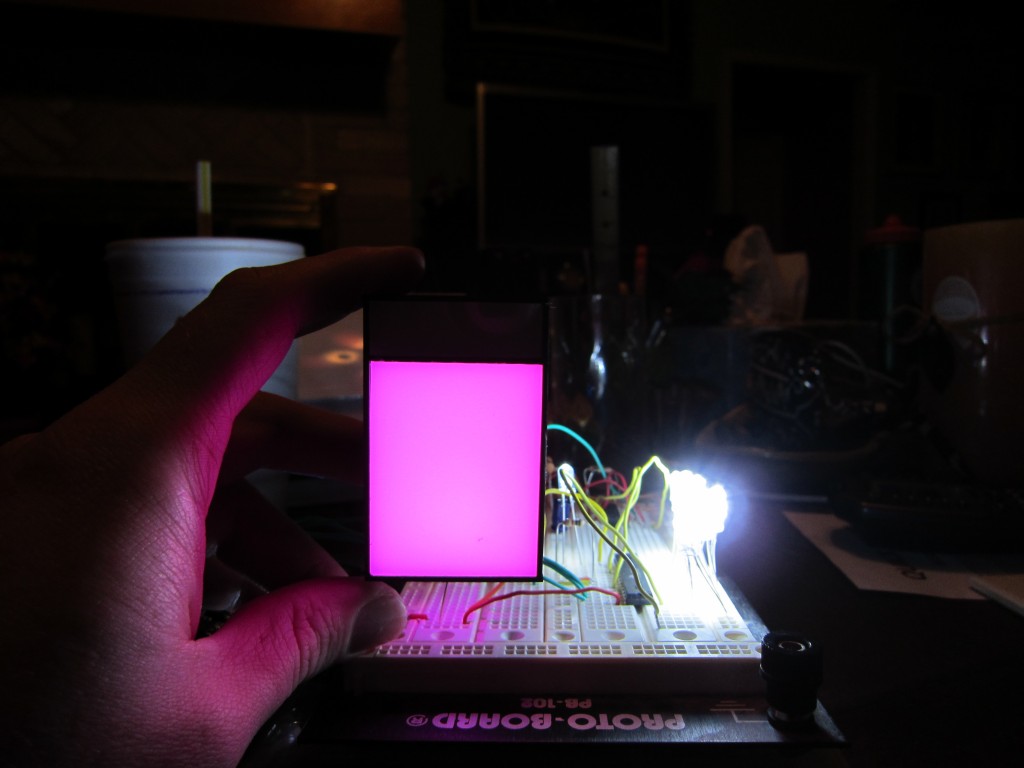

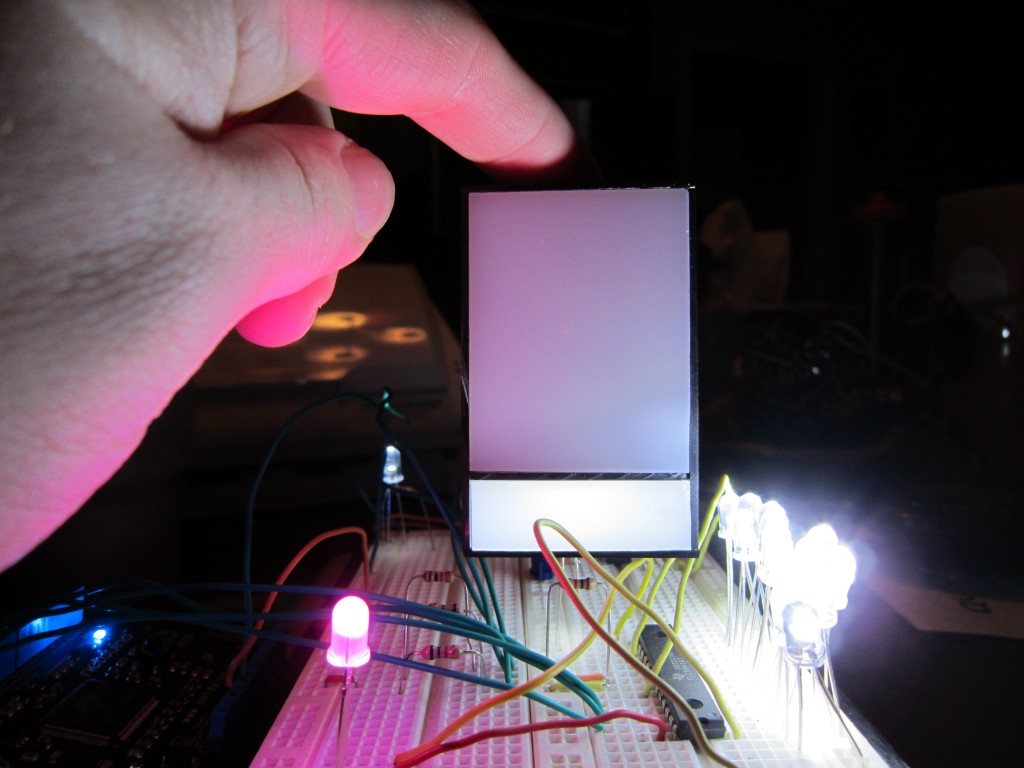

The same hobby shop also provided me with my plastic solvent adhesive, which it was now time to try out. After a first attempt at thinking I knew better than the instructions failed, I actually followed what the bottle said to do, holding the pieces in place as I wanted and brushing the solvent along the seam. Success! After a few rounds of this, my prototype space with white lining and support was ready to roll. Now, the big test, lighting it up with both the color and white LEDs, for the main body of the space and the color bar, respectively. How did it work? Judge for yourself.

The same hobby shop also provided me with my plastic solvent adhesive, which it was now time to try out. After a first attempt at thinking I knew better than the instructions failed, I actually followed what the bottle said to do, holding the pieces in place as I wanted and brushing the solvent along the seam. Success! After a few rounds of this, my prototype space with white lining and support was ready to roll. Now, the big test, lighting it up with both the color and white LEDs, for the main body of the space and the color bar, respectively. How did it work? Judge for yourself.

Ignore all the not-interesting LEDs on the protoboard. This testing shows pretty darn good color mixing and distribution, very minimal darkening at the edges due to the supports, and an acceptable amount of hot spotting, all based on lights being driven by the LED driver I plan to use. (Really, the hot spot is even less pronounced in real life than in the photos, as the camera liked picking up the hot spot more than the eye does.) I still need to work on getting my tolerances down for fabricating the pieces, and I need very badly to build some rigs to make the assembly a reliable, repeatable process, but this is looking very promising for getting the kind of effect I want. I also have some ideas about just how deep the various pieces need to be, so I can start doing some actual planning and cutting for pieces that will actually go in the board. Progress is fun!

Going Back and Forth on This

So, crystals came in. Because I failed to actually check the Amazon listings very carefully, I just ordered the first crystals I saw, which were marked as 16.0 MHz. After the order was placed and on the way, I see that the chip I’m using may not be happy with anything more than 3.0 MHz. Oops. Well, may as well try it anyway.

Hooked up the crystal in the circuit as demonstrated in the previously discussed page, and was pleasantly surprised to see the timing LED firing much more quickly than with the RC circuit. Not only that, but the fact that it was firing at all was a positive sign! Maybe it’d work with this frequency after all! Well, let’s just connect the rest of the circuit back up and see what happens.

Well, better results, but far from acceptable. I can see the PWM beginning to occur, but it’s not really working, so much as turning the LEDs on and off… very… slowly… Drat. Well, I can play around with some resistor and capacitor values to see what I can do, but that’s just not going to cut it. I hooked up a logic analyzer and saw some interesting results. The analyzer can only sample at 24 MHz, so I can’t expect to get a regular 16 MHz signal fully captured, but I should be able to see something. And something I did see. A very erratic signal, with a short burst of regular pulses that measured around 7 kHz, followed by long stretches of no pulses whatsoever, then another burst.

This means one of two things the way I figure. Possibility A is that I’m really just not reading it well, and the signal is fine, and I’m just missing 95% of the pulses. Possibility B is that something is still very wonky with the circuit, possibly due to the load of the other chip, and it’s just too fragile and sensitive to be reliable in the current configuration. Considering that I also was tracing one of the higher count lines, and its pulses only seemed to occur when the bursts I did record occurred, I’m thinking option A is far more likely.

So, another timing option come and gone. I could go ahead and order another batch of 50 crystals for a different frequency, but instead I’m going to turn to Digi-Key, who a coworker conveniently pointed out is willing to ship USPS first class mail for cheap. I’ve got three different frequencies of actual oscillator chips on order, which I’m hoping will be far more resilient to the vagaries of my circuit that these RC and crystal configurations have been.

Gather Ye Crystals

After finally getting all the bits together, I was able to get the binary counter hooked up and working, based on some information I found on another site. Connected an RGB LED to some of the higher value outputs, and watched in amazement as the little diode color shifted before my eyes. White(ish), magenta, cyan, blue, yellow(ish), red, green, blank, repeat. After a few failed starts, seeing this was pretty happy-making. Of course, it wasn’t going very fast, but that could still be okay. So, it was finally time to try hooking up the LED driver to test the next step, which also required hooking in the Netduino, so I can ensure the driver knows to light the LEDs.

And that’s where things started to go a bit downhill. After hooking things up, I could tell the Netduino was controlling the driver okay because it did actually light the LEDs, but suddenly the counter sample LED I hooked up wasn’t cycling nearly as fast. Well, not usually, anyway. In some instances it would speed up, then slow down again. Regardless, it was never quite fast enough to actually make the driver do its PWM correctly. (As a side note, the times the thing would speed up reasonably well seemed to be directly related to when I would actually physically hold the protoboard with my fingers. Apparently human capacitance has an effect on this circuit as it stands, which is hardly the desired effect.)

My best guess right now is that the added power drain of the LEDs and the driver are somehow affecting the RC portion of the oscillator circuit, which makes that approach of questionable value. The counter ‘s internal oscillator can also be used with an external crystal, however, so that was my next plan. Rather than paying for shipping though, I decided to see what I could find on Amazon. Did you know you can get a package of 50 crystals for about $7.00, with free shipping? Did I need 50 crystals? Not at all! Did I feel better about paying $7.00 for 50 crystals than paying about $5-$8 for one crystal with shipping? Absolutely! So, now I wait for the crystals to arrive, and retest the circuit.

-

Archives

- November 2012 (2)

- October 2012 (1)

- September 2012 (4)

- July 2012 (2)

- June 2012 (7)

- May 2012 (6)

- April 2012 (5)

-

Categories

-

RSS

Entries RSS

Comments RSS